Product Description

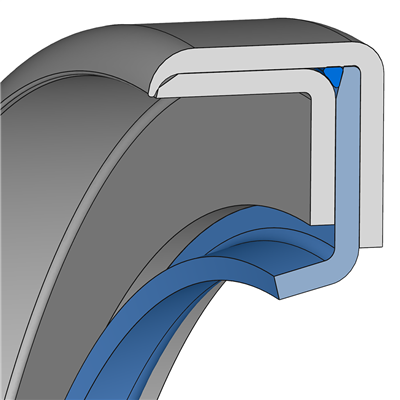

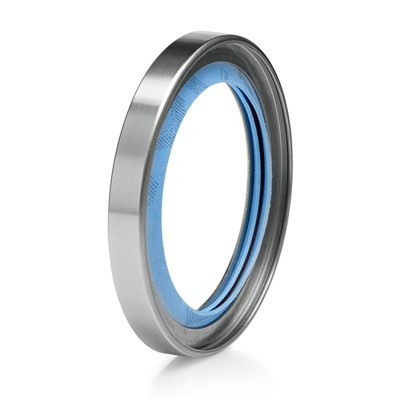

The PTFE lip seal is a rotary lip seal that features an ID lip that seals dynamically on a shaft and metal casing on its OD to seal statically press-fit into a bore. A gasket is sandwiched between layers of sealing lips and the can to seal off the potential leak path. Since the lip is not spring energized, the radial lip contact forces are lower than a rotary lip seal, which allows the seal to function at much higher surface speeds (up to 30m/s).

The seals are manufactured from a wide variety of PTFE composites and other machinable plastic materials. Standard gasket choices are fluorocarbon, nitrile. Metal is stainless steel. This broad foundation of standard gasket, metal and PTFE materials can be tailored to suit nearly all applications.

Used in this Product

The most popular fillers for products are graphite, fiberglass/molybdenum disulfide, carbon fiber and mineral.

Common Materials

Molybdenum disulfide increases the hardness of the seal surface while decreasing friction. It is normally used in small proportions combined with other fillers such as glass. MoS2 is inert towards most chemicals.

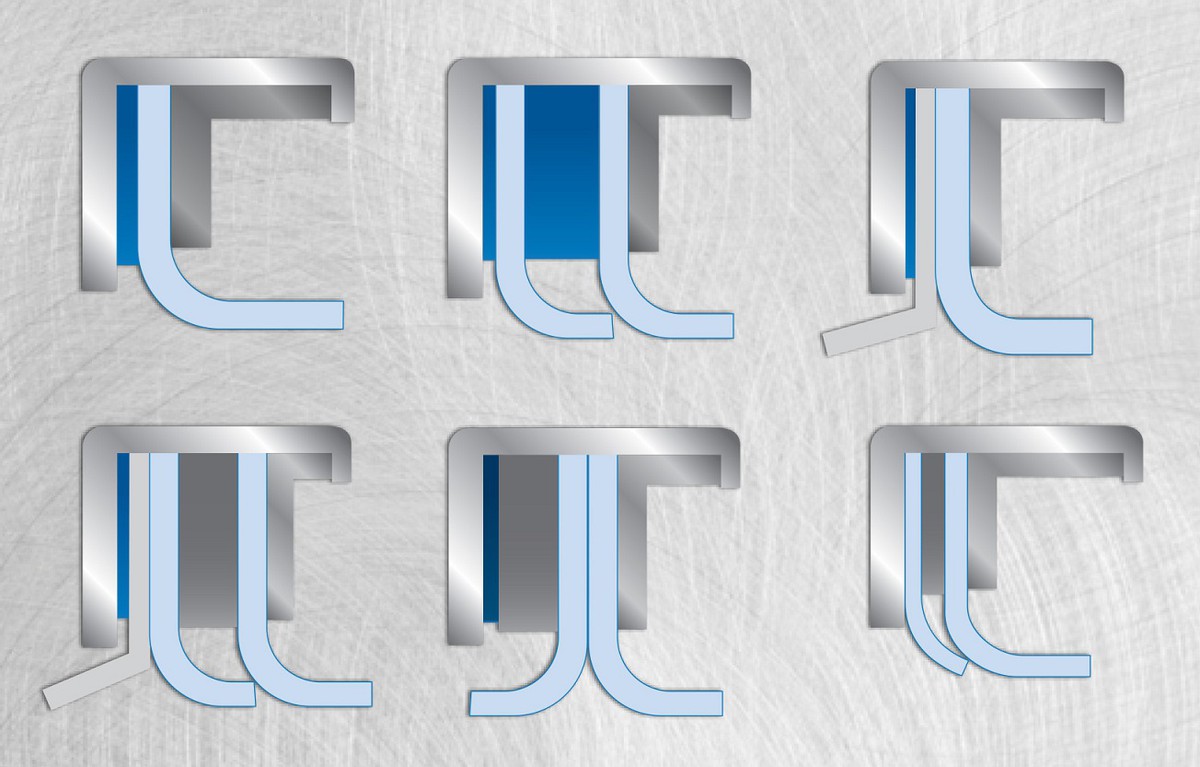

Formed Primary Lip

General purpose rotary shaft seal.

Applications

• Motors • Gear Boxes • Pumps • Bearings • Compressors • Cryogenics • Extruders • Valves • Blowers • Spindles • Robotics • Mixers •

Markets

Aerospace • Automotive • Chemical Process • Appliances • Machine Tools • Marine • Medical • Pharmaceutical • Military • Heavy Machinery • Pulp & Paper • Hydraulic • Food Processing • Electronic • Oil & Gas • Steel Mill • Plastics

Stainless steel good chemical resistance properties up to 600 °F. resists corrosive media up to 400 °F.

◆◆ PTFE+SS304

| Material description | Filled PTFE (such as MoS2/Glass fiber, Ekonol and so on), or Virgin PTFE is available |

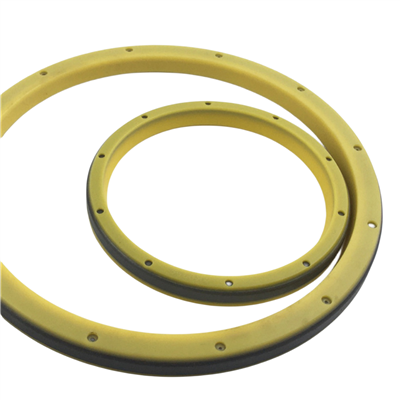

| Available Color | White, black,yellow |

| Material Strength | Virgin PTFE can meet the requirement of food grade approval.

And PTFE oil seal has good anti-friction performance, suitable for harsh working conditions such as poor lubrication, high speed, high temperature and strong corrosive medium. Lip with threads has good sealing performance. |

| Temperature | -80~+200℃ |

| Speed | ≤30m/s |

| pressure | ≤10bar |

| medium | Mineral oils,synthetic oils,greases |

| Applied device | Compressor cylinder |